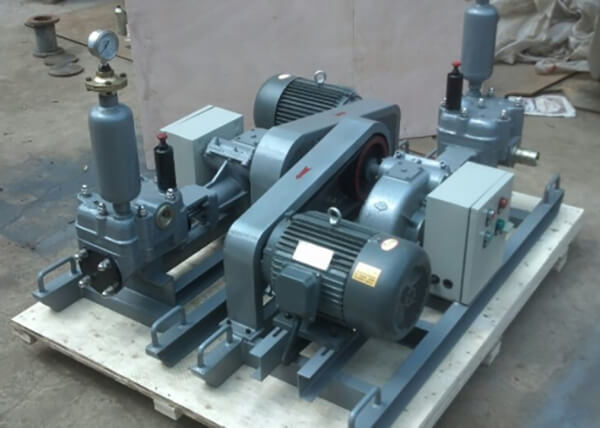

Mini grout pump for sale

Mini grout pump for sale are characterized by small capacity, light weight, energy saving and power saving, pulseless large capacity discharge, high working pressure, and convenient movement.Mini grout pump for sale is an ideal mortar carrier for small and medium-sized projects. Gaode Co., Ltd. Is a professional manufacturer of grout pumps that integrates scientific research, manufacturing and sales. Since its founding more than 10 years ago, the company has been constantly innovating in technology and management, developing grout equipment products suitable for the rail, hydro, transportation, coal metallurgy, geology, mining defense and chemical industries.

The performance and quality of grout pump for sale plays a decisive role in the safety, quality and efficiency of grout projects.

The main advantages of mini grout pump for sale are short grout holes, portable drilling rigs can be used, hole tilt is easy to control, grout effect is good and easy to detect. The disadvantage is that grout construction occupies the well construction period and the downhaul operating conditions are poor. This method can be applied to situations where the aquifer is deeply buried or the distance between the aquifers is large. Cement grout pumps for micropile can inject mortar, mortar and cement slurries, as well as spray with an air compressor and spray gun. Grout pumps for micropile are mainly used for grout reinforcements in tunnels, railroads, tunnels, hydropower projects, etc.

The mini grout pump for sale are a new type of micropile construction method, and the main processes are as follows.

1. Using an excavator, drill a hole with a diameter of 0.25m to 0.4m in the foundation.

2. Pour clean water into the drill hole from the hollow drill pipe of the drill rig to clean the hole once.

3. Remove the drill pipe and insert the steel cage and injection pipe into the drill hole.

4. Pour clean water into the borehole through the perfusion catheter to clean the hole twice.

5. Pre-prepared fine stone concrete is injected into the borehole through an injection pipe, and fine stone concrete is injected through the borehole to form a micropile with a diameter of 0.25 m to 0.4 m.

The strength of the pile body after driving the pile by the conventional stone grout method is relatively small, which greatly affects the bearing capacity of the micropile. The mini grout pump for sale controls the strength of the pile by constructing fine stone concrete with different strength grades, and effectively guarantees the strength of the pile of the produced micropile.